-

Approving with ISO9001,ISO14000 and OHS18000 system.

-

Certificates of TUV, CQC, CGC, JET and CE.

-

800MW capacity.

-

Efficiency & Reduction & Security

-

3000PCS/h & 4000PCS/h high-speed series welding machine, full-automatic lanminating welding machine, two-way fully automatic guling frame machine, and supporting assembly line with 355 beat.

-

The automatic low fragment percent series welding machine, full-automatic glass loading machine, and the high-precision fully automatic backing plate/EVA the raw material loss of each product minimal. At the same time, the cutting and paving machine allows for the raw material loss of each product minimal. At the same time, the process is controlled to a minimum thus reducing labor costs and subsequently keeping material costs low

-

Our product quality is assured as the it surpasses the strictest quality control procedures and testing.

-

Controllable production process

-

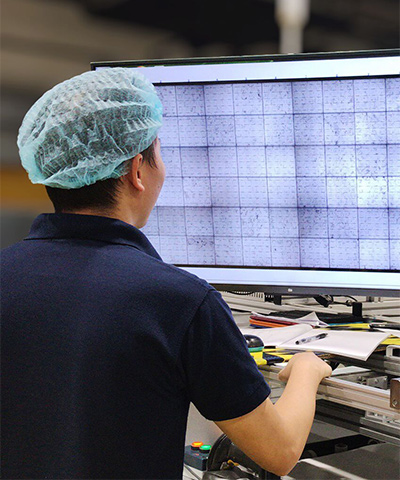

SOLARLAND uses industrial cameras with the high pixel with high-definition and high-contrast to monitor the production line from the control of the ramaterials, to the lamination process to the final testing stage of the product.

-

The laboratory level 3A PASAN tester is used on the production line, so as to measure the accuracy of power of each piece of module.

-

With our MES software we can automatically monitor our machinery and collect data directly from equipment and operators on the shop floor in real time, eliminating inaccurate and time-consuming anual data collection. It is a proactive option to anticipate and solve production problems before they occured.

-

Photovoltaic module

-

-

-

-

CN

CN